Who invented the Rocket Stove? And, even cooler facts about rocket stoves, rocket mass Stoves, & wood stoves

Updated, 2/14/24

Who invented the rocket stove?

The rocket stove was invented in 1982 by Dr. Larry Winiarski of the Aprovecho Institute (an holistic, permaculture, education laboratory in Oregon) as an improvement over traditional wood fire cooking. The institute was motivated to provide better cooking solutions for countries suffering from the negative health effects of breathing wood smoke (the equivalent of 3 packs/day of cigarettes for some children; see this post on wood stoves vs. natural gas, a debate that might be made moot by the rocket stove) and the logistical and environmental impacts of burning scarce wood inefficiently (see this excellent video). The institute succeeded in their quest and now work hard to make sure the world has the stoves needed.

Significance of rocket stoves for thriving on one planet’s worth of resources

Energy and heat are two key physical technologies (to be used on conjunction with social technologies) in moving from our dysfunctional status quo to a future of thriving on one planet’s worth of resources (one planet thriving). Multiple solutions are necessary, including stirling engines, alcohol, biofuel, and more.

The challenge in shifting to sustainable energy is cooperating with people to make it happen. That’s where my training, Kindness for a Change, comes in. In addition to a whole module dedicated to physical technology, the training includes the synergy between individual wellbeing, connected relationships, healing our politics, and healing our planet.

Start with traditional wood stoves

Anyone who lives in a cold climate and has checked out Ben Falk’s fantastic book, The Resilient Farm and Homestead: An Innovative Permaculture and Whole Systems Design Approach, will be inspired to

think hard about making a good wood stove central in their home design. Ben Falk’s wood stove, a Waterford Stanley (an older version of the one pictured here), burns about 2 cords of wood each season and heats his home, cooks his food, provides hot water, dries his clothes and various food items, and — of course — provides a cozy center (see this very cool video where Ben Falk describes all of these functions and more).

Now, what about rocket stoves?

But, before deciding on a wood stove, consider a relative newcomer on the scene — the rocket stove (which becomes a rocket mass heater when combined with suitable thermal mass). It uses 70-90% less

wood than a wood stove, burns cleaner with 1% of the footprint of an electric oven, and more reliably. How much wood is really required? The picture (right) is the typical amount of wood used by Ernie and Erica Wisner in their rocket mass heater per day. They use about double that for really cold days (2 cubic feet). As a result, a cord of wood will last them about four months or about 1.5 cords for a 6-month heating season. Note that this compares to 2 cords for Ben Falk’s system and so, in this comparison, the claims of 70-90% less wood use is not substantiated.

Given these potential improvements from rocket stoves, I started on a quest for a rocket-type stove that would meet all the functions of Ben Falk’s wood stove but with all the efficiency of a rocket stove. Silver Fire has many offerings but none that fit the bill. For a beautiful, and wood-stovey feel, Matt Remine at Walker Stoves uses his riserless

core to create a masonry cook stove and oven that looks great (see picture). He sells plans to make several different models of stoves.

There is also a rocket oven designed by Tim Barker that has risen to the top of the pack in some ways, combining reliability, ease of use, fast heating, ease of building, efficiency, relatively low cost, and flexible use. This

stove is detailed in Tim Barker’s book, The Rocket Powered Oven. Tim Barker and Tyler Morrison show how to build the most recent version of the stove (it has been improved in small ways since publication of the book), in a DVD released in 2018 by Wheaton (with several smaller supplementary videos) as a result of a successful kickstarter. 3D designs of each build in the DVD are posted online with the 2018 plans available here for $20. In addition, here is a short 3D sketchup overview of the oven. This oven uses Walker Stoves J-core plans. These same plans make a great portable cooker as well according to Walker (see his video here). In this video, Mathew Walker talks about where to get materials. This video shows the oven in action, including how little wood it requires.

Portable Rocket Stove for Cooking

If you look online you can now find half a dozen stoves that are advertised as rocket stoves, like this one. But as attractive as this kind of stove might be, it is not a rocket stove and will not benefit from the design of a real rocket stove where dimensions and insulation are key. Unfortunately, there do not appear to be real rocket stoves on the market that are also portable.

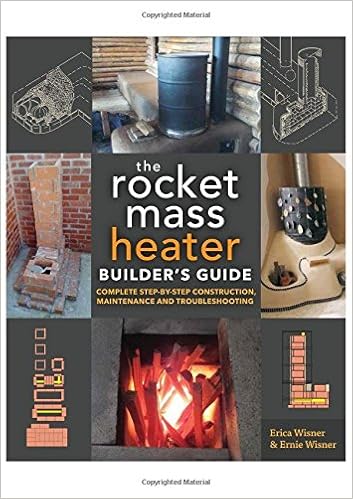

Matt Ramine Walker to the rescue! Matt has been on the rocket stove scene for years and has been featured in various workshops and design sessions with Ernie and Erica Wisner who wrote the book, The Rocket Mass Heater Builder’s Guide: Complete Step-by-Step Construction, Maintenance and Troubleshooting (below).

Matt has built beautiful and efficient stoves of all kinds and sells those plans at walkerstoves.com. The portable rocket stove we’re building is based on Matt’s Superhot J Rocket Stove Core plan ($55). Matt used to sell portable units that were wrapped in aluminum (video of Matt lighting such a stove here), and our stove imitates that design.

Questions for Matt:

-

“Tim Barker’s Rocket Powered Oven can sit atop this J rocket stove as well. So, in theory, this design can power a versatile setup.” Is that true?

-

What is the red angle plate on the riser side of the fuel hole pictured in your video of you lighting the aluminum-clad J?

-

At the end of that same video, you show a pot on top of the riser and there appears to be some kind of pot holder underneath. Any details on that?

-

Cost estimate?

Rocket Stove + Thermal Mass = Rocket Mass Heater

So, far, we’ve focused on cooking stoves. But, if you use a rocket stove to heat up a lot of thermal mass, such as a cob bench, you hav

Due to popular demand for even better video and sound demonstrations of rocket stoves, Paul Wheaton’s successfully funded Kickstarter campaign (March, 2015) made it possible to produce 4 more DVDs, released in September 2016, covering many aspects of building rocket mass heaters and their real-world outcomes (watch the trailer here and buy the DVDs here). These videos are excellent for understanding how to build, light, and maintain different types of rocket mass heaters. And, they also share the results of their experiments. See the notes below for more details.

What about building codes?

Before we get too excited, we might wonder whether building codes, mortgage lenders, insurance companies, etc. will allow a rocket mass heater in the home. The answer is a qualified “yes” if a rocket mass heater is viewed as a form of masonry heater, a type of stove more understood by mainstream systems. The only issue then is whether the rocket stove burn box and riser can be presented in a way that doesn’t seem strange or dangerous. For more on this, see this post at permies.com. With many sustainable technologies, it would be very valuable to have a team who worked on creating a prototype set of plans and systematically get them approved by various municipalities as a seed for others to get them approved in their areas.

Notes on DVDs

DVD 1: Cob stoves, including tipi heated well with a cob rocket mass heater.

DVD 2: Pebble stoves. The mass is composed of loose rock and gravel rather than something like cob.

Lessons learned from DVD 2: Pebble style (about 1:35 in video):

- Prefer cob rather than pebble

- Chimney/Exhaust performs better the higher the exit point is. Ceiling is best.

- Chimney should go closer to the barrel — slightly less efficient but it burns clean and well.

- Drying wood over the mass works really well

- Still Experimenting with ceramic fiber cores

- Useful clay? Make a pancake and it dries without cracking at all or very much.

2:10 in DVD 2, Paul reviews lessons from Shop pebble stove:

- Pebble style not as good as cob and holds about 25-30% less heat than cob

- Pebble is more transportable (2 hours), much more flexible to make changes, and better aesthetic for some people

DVD 3: Ship-able Cores.

This would help take rocket mass heaters mainstream b/c it would make it easier to build. Two years of experiments with 3 different design paths:

(1) Pourable Cores. Most failed by cracking though there are some that seem to work.

(2) Wood box ship-able cores. Work well. Heavy to carry (2-4 people to move depending on how dry it is). They use fire brick for the botton, 1″ dura board for insulation, and add a mixture of perlite, clay, and wool that they call “cobbish”. Total material cost is $250. Fire box is 16″ tall minimum (b/c that’s a common length to cut wood). The heat riser needs to be >= 3 x the height of the fire box (48″). Barrel has to be 2″ taller than that. Most difficult part of a rocket mass heater is the manifold. if you are using 8″ round duct work, the square portions of your core (the fire box, the burn tunnel and the riser) must move the same volume of air — in a square that equates to 7.09″ on each side. The riser can be round or square, but if place round riser on square base, a bottle neck gets created. There are limitations on how long the burn tunnel can be. 1:21:30 is a shopping list for version 1.2. Version 1.3 has not been built but may reduce materials by 35% – Plans can be found on permies.com/biggs

(3) Ceramic cores (wood box, fire tunnel and riser). Initial fires result in smoke until rice starch burns off. They cost $700 but might come down to $70 with sufficient quantities. They work “magnificently”. They then experimented with a 4″ system (instead of 8″) – cheaper, easier to ship. Paul Wheaton guesses that a 4″ system behaves like a normal 6″ and 6″ like a normal 8″. Never use steel in burn tunnel or riser (it melts!) and possibly not in the wood feed. Wheaton is moving away from using perlite and vermiculite in core because they get soft and squishy around 1400 degrees F.

(4) Future Cores. Shipped to your door for ~$500. If materials cost was $100 and met UPS qualifications for cheap shipping, that would leave room for profit. 2 designs that might do this: (a) duraboard wrapped in portland cement and perlite mix. Portland cement (needs 28 days to cure) spawls at 600 degrees F so has to be protected by duraboard. (b) Ceramic core in 4″ system.

[UPDATE as of 2/14/24 – Matt Walker has honed things to such a degree that he is now selling plans but not the products themselves.]

DVD 4: Innovator’s Event (2014), featuring Erica and Ernie Wisner, Peter van den Berg, Tim Barker, Matt Walker Remine

The manifold: The place where cooling gases coming down the barrel gets distributed to the chimney or the mass. Shape is key. Also, it’s a place where some ash settles so a space is needed below the pipe to the chimney or mass. Useful to have a clean out port in that area (1-2/year assuming you are not burning paper). Danger is creating a bottleneck when it’s so tempting to create a bottleneck. 1/3 of a barrel cut to fit around the riser and tunnel and with a hole for the exhaust makes a good manifold. On camera, they build a circular (better for not cracking) and then a square manifold out of brick. Space between exhaust duct and side of riser should be 4″.

“The Smoker” by Matt Remine (see below for examples of his stuff also). Emphasis on the stove as cooker and smoker. Fluid dynamics (and some thermal dynamics) relevant here. Imagine heat as water just upside down. Hot air rises and colder air will spill out the bottom. This way of conceptualizing things offers possibility of less ducting and more bench shapes. This is all explained by Matt and Paul about 40 mins into the DVD.

“Ring of Fire” by Matt Remine. Watch the fire and get a warm butt (featured image is a version of this). Glass for the wood feed and the burn tunnel. Wood stove glass can tolerate temps up to 1300 degrees F, a problem when trying to get temps up to 3,000 degrees F. Also, you lose heat out through the glass. Instead of ducts, you have half barrels turned upside down — heats up faster so warms butts faster but holds heat for far less time (an hour instead of a day).

Notes on using and prepping barrels. Don’t use a barrel unless you know what was in it previously! It could have been toxic. Or, if it was old fuel, you could blow up! How to prepare your barrel (1:09:55).

“Shirley Temple” by Ernie Wisner is small but creates multiple fire vortexes to allow the smoke to burn, as if the burn tunnel were longer. The same is true for creating vortexes in the riser — it can appear, to the fire, as if its longer than it is. This is some of the reasoning that has been used by Matt Remine in creating his riserless core (plans are free for personal use). Another example of how important fluid dynamics are: fire acts like water in its movement.

“The Cockit and Lockit Rocket” by Tim Barker. His interests are primarily cooking and heating water. The 6″ system he designed at this event had a temperature-controlled griddle, an oven, and a hot water system. With hot water systems, it’s easy to go squish boom if you do it wrong. So, they don’t get into the details about how to do it. Note, the oven part of this design is featured in a 2018 DVD, summarized above.

The “Batch Box” by Peter van den Berg. Instead of a J style, people like them because you can load wood through a door like you are used to and also view the flame. This 8″ system was the second one built at the time and Peter says it is twice as powerful as the 6″ systems he builds more regularly. Attaching doors is non-trivial or expensive to have it custom made ($300 range). Correctly sized “P-channel” is critical but details not covered in this DVD series (however, see this page from Matt Remine for links to Peter’s designs and Matt’s modifications of them). It heats the space rapidly, holds more wood, and is a much cleaner burn.

[restrict …]

Donal’s links here. [/restrict]

More about Rocket Stoves and Rocket Mass Heaters

Milkwood in Australia has posted plans and pictures for

Matt Remine (of Walker Stoves) demonstrates a great multi-use, outdoor design with visual flame, slate benches, and cooking (see picture at top). These are his latest versions, including heated benches, pizza oven, and more. Check out his whole series! Note that this is a “batch box” style rocket mass heater where the flame can actually be made more visible (this is a cool example too with plans). He also has a beautiful kitchen stove on his site.

Here is an article for an outdoor rocket-powered shower. And, another article by the same folks, assembling knowledge about cooking with rocket stoves, among other things.

What about building codes? See this post.

Rocketstoves.com is a terrific site for all kinds of articles and details about rocket stoves

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Pingback: Wood vs. Natural Gas for Environmental and Personal Health | One Planet Thriving

Pingback: Restoring Forests and Communities: Willie Smits | One Planet Thriving

Pingback: Donal’s Private Goodies | One Planet Thriving

Pingback: Thriving on One Planet: The Big Picture | One Planet Thriving

Pingback: Solutions for a Functional Future | One Planet Thriving

Pingback: Alcohol: A Renewable Energy that Sequesters Carbon and Can Power Our Lives? | One Planet Thriving

Pingback: The Four Principles of Sustainable Life | One Planet Thriving

Pingback: The Energy of Stirling Engines – Notes | One Planet Thriving

Pingback: Using Dehumidifier Water in Valuable and Effortless Ways. Mine Does Laundry. | One Planet Thriving